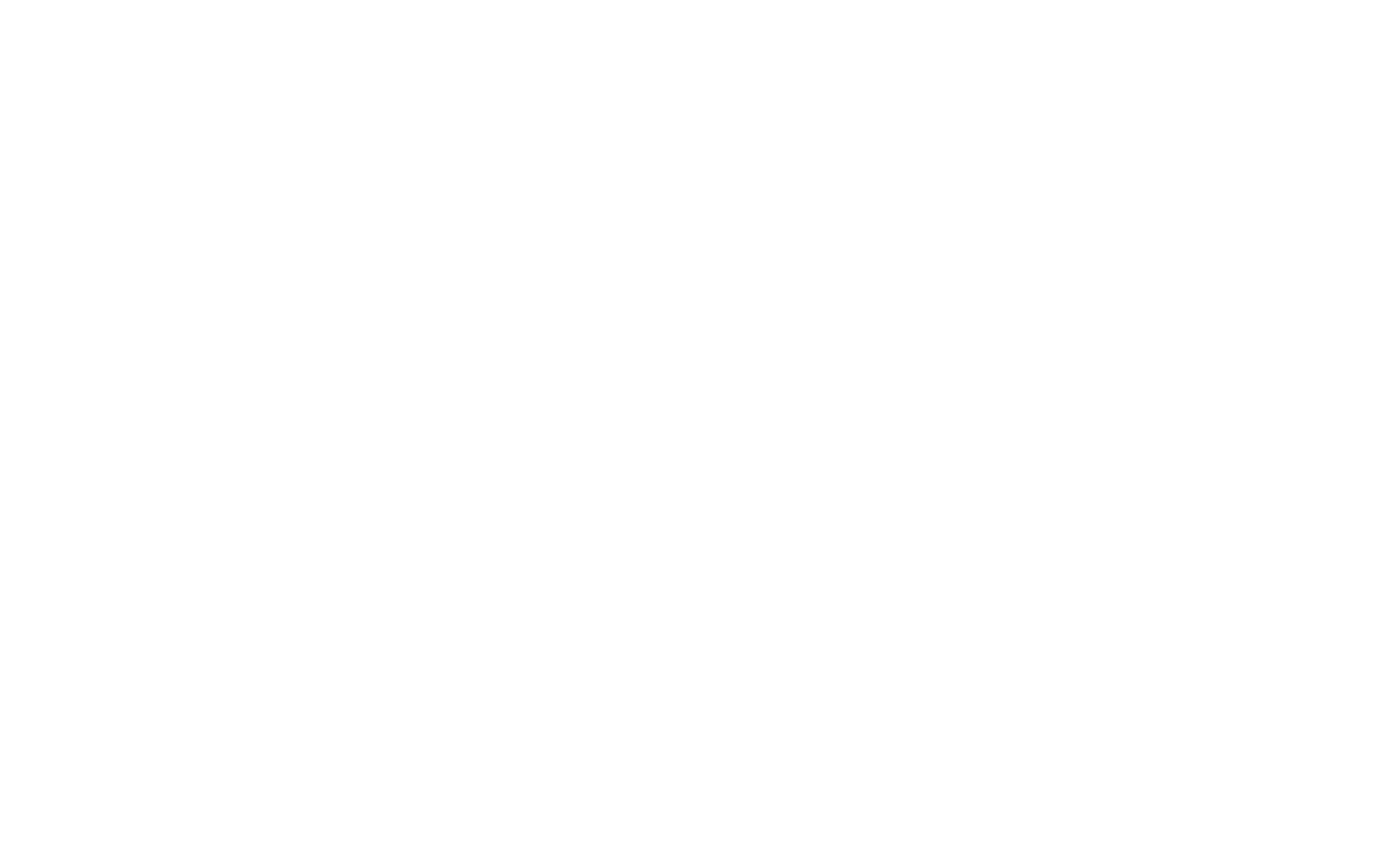

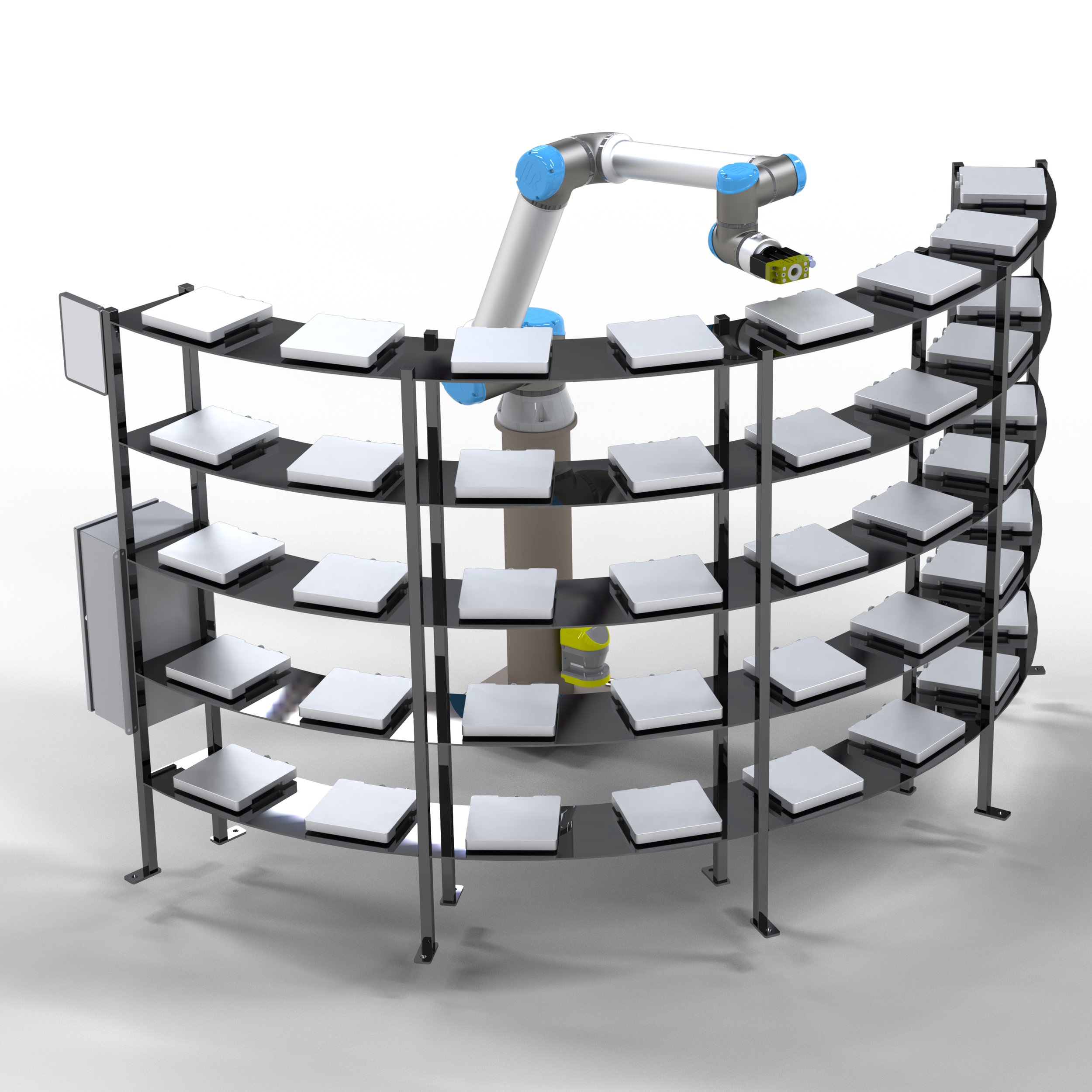

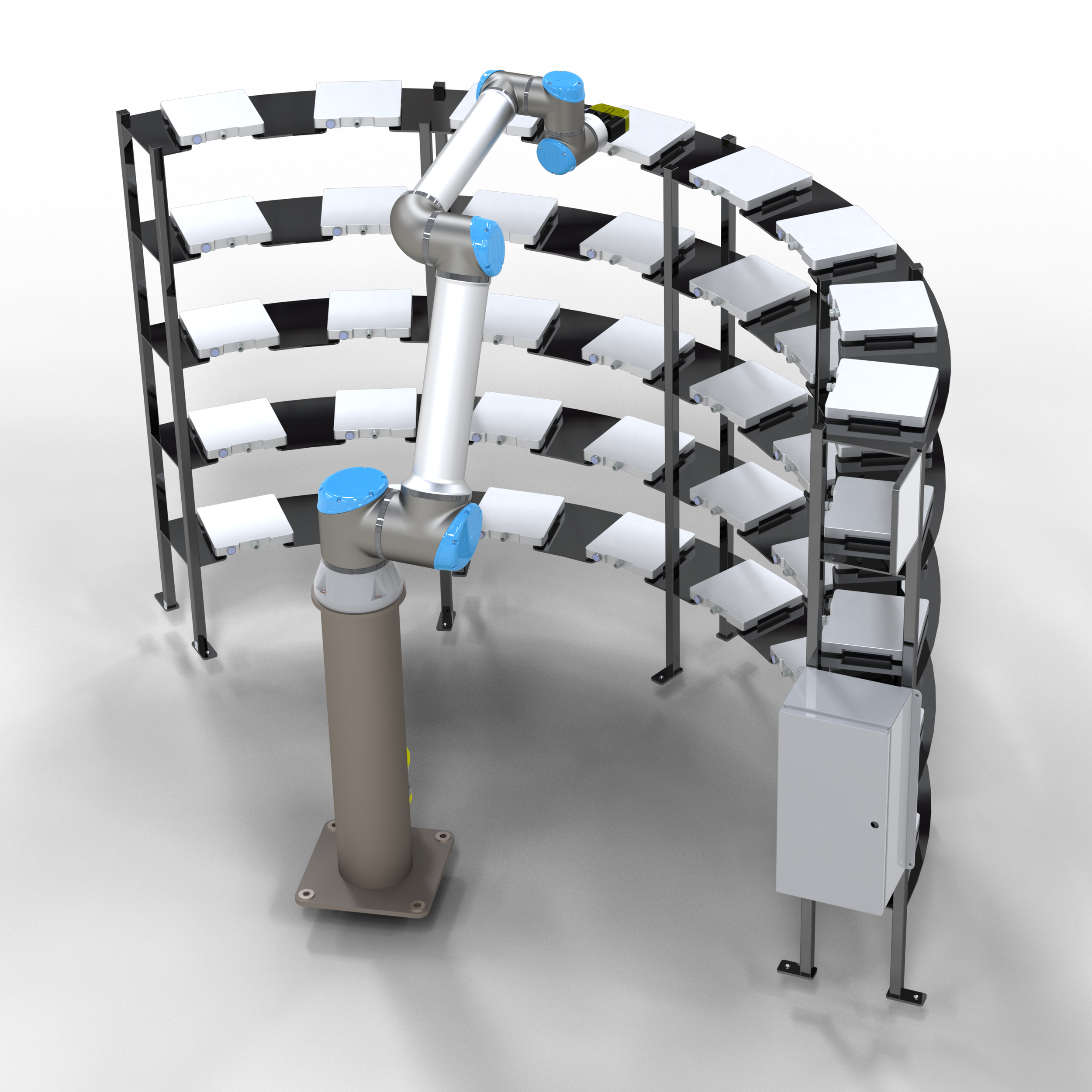

Orion 40

Unleash Stellar Profits, Even When the Stars Are Out!

Now shipping with the Schunk zero-point system!

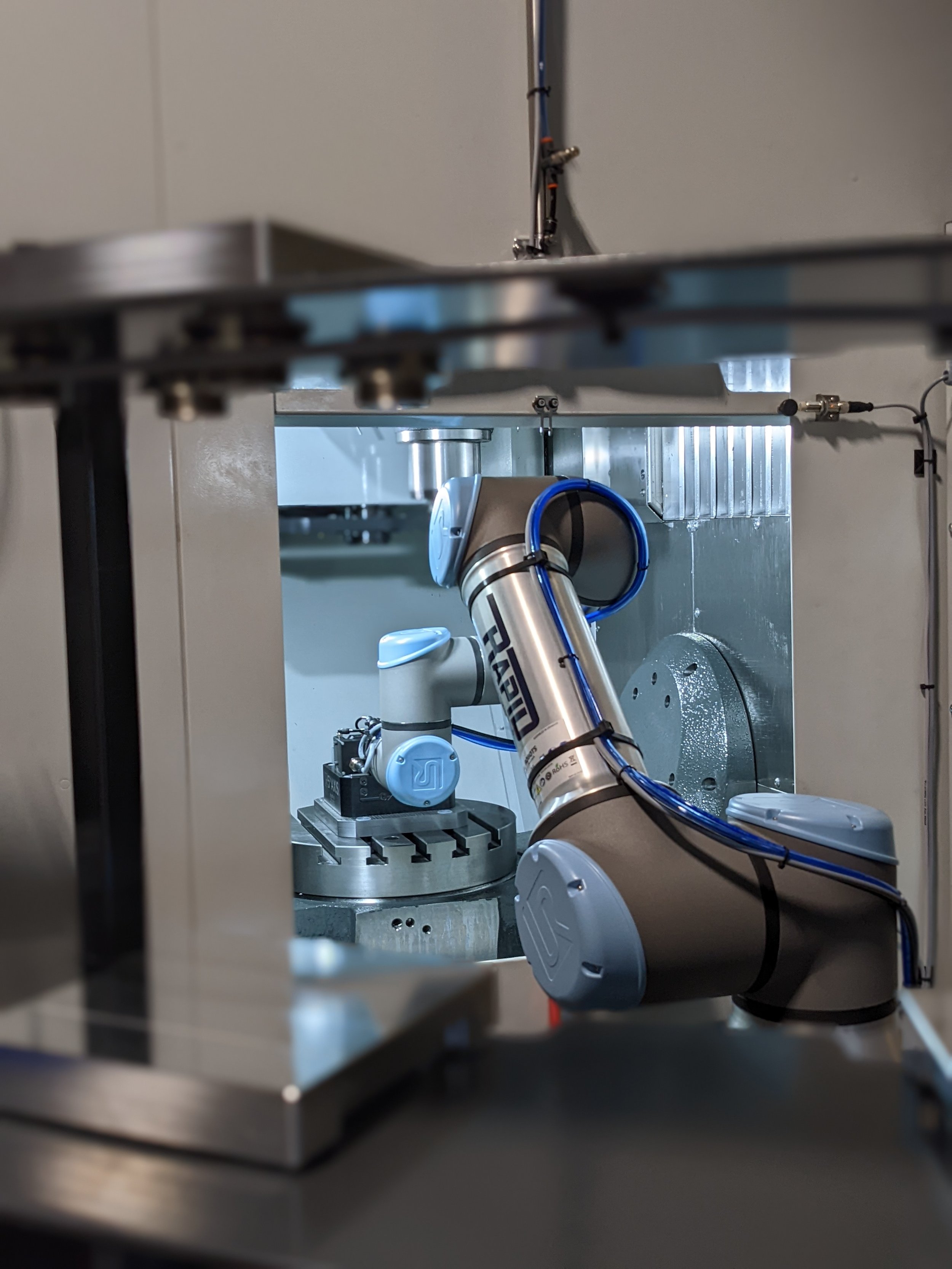

Experience the next level of machining operations with Orion, our state-of-the-art collaborative robot cell designed to automate and streamline the loading and unloading of pallets for a wide variety of machining centers. Inspired by the brilliance of the Orion constellation, this cutting-edge solution boosts productivity, ensuring your workshop operates at peak performance.

Unleash Stellar Profits, Even When the Stars Are Out!

Now shipping with the Schunk zero-point system!

Experience the next level of machining operations with Orion, our state-of-the-art collaborative robot cell designed to automate and streamline the loading and unloading of pallets for a wide variety of machining centers. Inspired by the brilliance of the Orion constellation, this cutting-edge solution boosts productivity, ensuring your workshop operates at peak performance.

Unleash Stellar Profits, Even When the Stars Are Out!

Now shipping with the Schunk zero-point system!

Experience the next level of machining operations with Orion, our state-of-the-art collaborative robot cell designed to automate and streamline the loading and unloading of pallets for a wide variety of machining centers. Inspired by the brilliance of the Orion constellation, this cutting-edge solution boosts productivity, ensuring your workshop operates at peak performance.

-

-

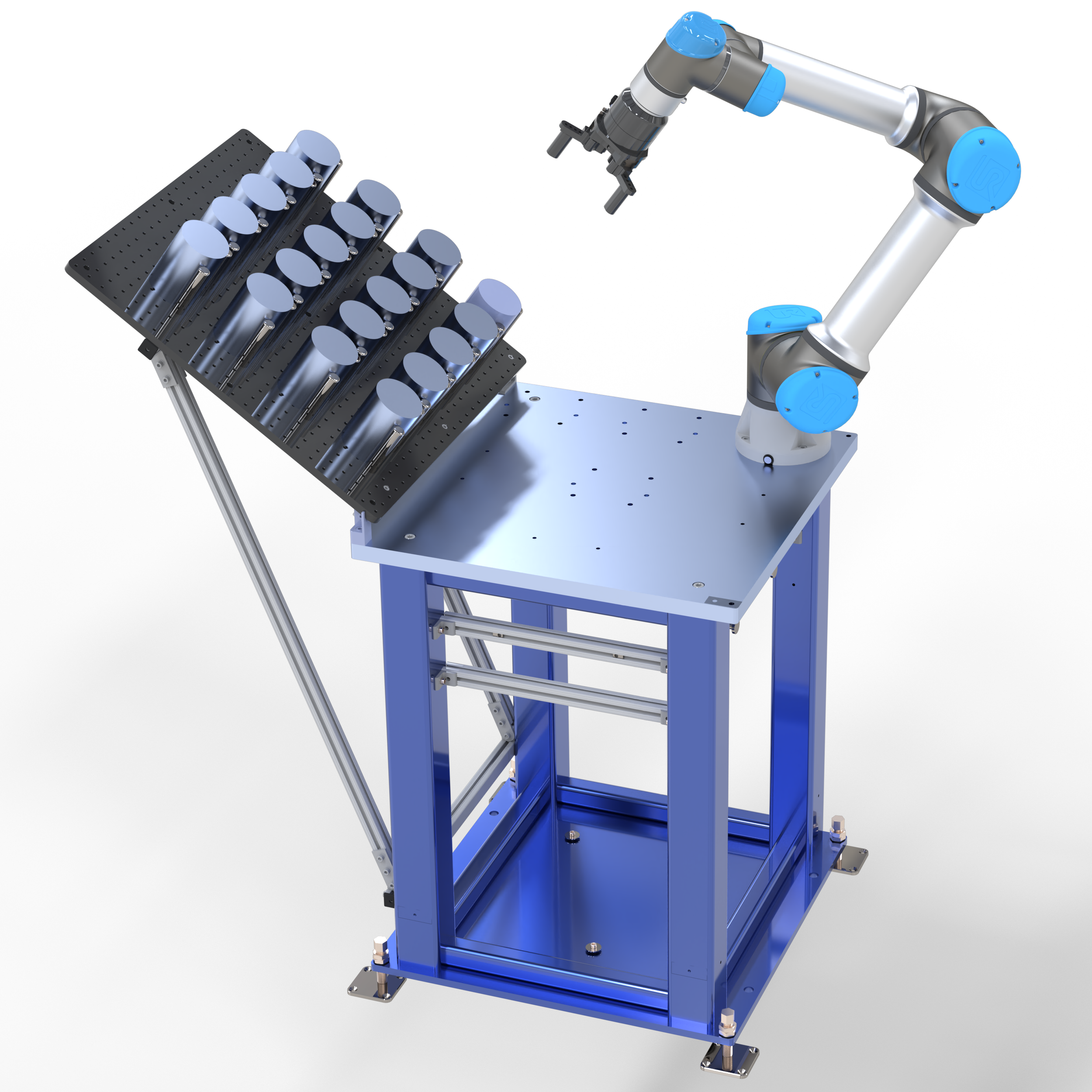

• Universal Robots UR10e collaborative robot

• 40 pallet capacity

• Square pallets available in 3 sizes

• Weight capacity by pallet size:

o 5.90” (150mm): 19.8 lbs. (8.98Kg)

o 7.87” (200mm): 17.2 lbs. (7.80Kg)

o 9.84” (250mm): 13.9 lbs. (6.30Kg)

• Work Envelope:

o Top Shelf:

• Metric: 300mm x (Pallet size minus 7mm) x 275mm

• Standard: 11.8” x (Pallet size minus .275”) x 10.83”

o Bottom 4 Shelves

• Metric: 260mm x (Pallet size minus 7mm) x 210mm

• Standard: 10.25” x (Pallet size minus .275”) x 8.26” -

• An intuitive Human Machine Interface (HMI) for easy scheduling and assigning of pallets

• Equipped with a Schunk VERO-S NSR robot coupling & Schunk VERO-S NSE zero point system for seamless pallet handling and efficient robot-to-pallet connections

• RFID pallet recognition system ensures quick and accurate identification of pallets, streamlining your workflow and enhancing overall efficiency

• Integrated pneumatic auto-door with open/close sensors

• Well-polished pneumatics and wiring for smooth and efficient operation

• Advanced robot programming for reliable loading and unloading of pallets

• Seamless CNC communication via Ethernet allowing for precise control of NC program selection, cycle start, and completion monitoring

• Inclusive advisory safety risk assessment per ISO 10218-1, 10218-2, 12100, TS15066, 13850, and 14120 to ensure compliance and safety

• Before installation, our team will work with you to ensure your shop is prepped with the necessary power requirements, shop air hookup, power receptacle and correct pallets for your application