Image 1 of

Image 1 of

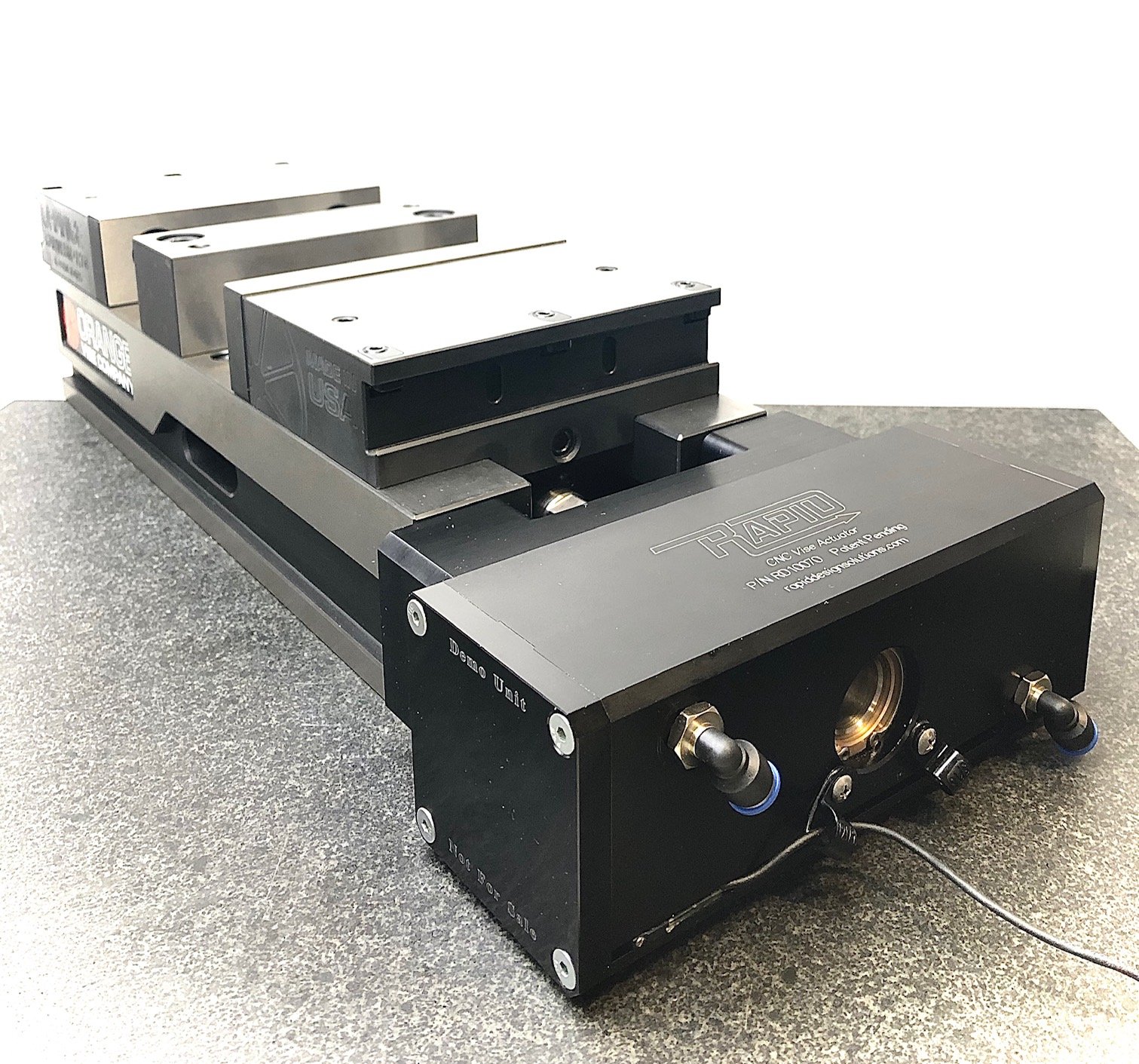

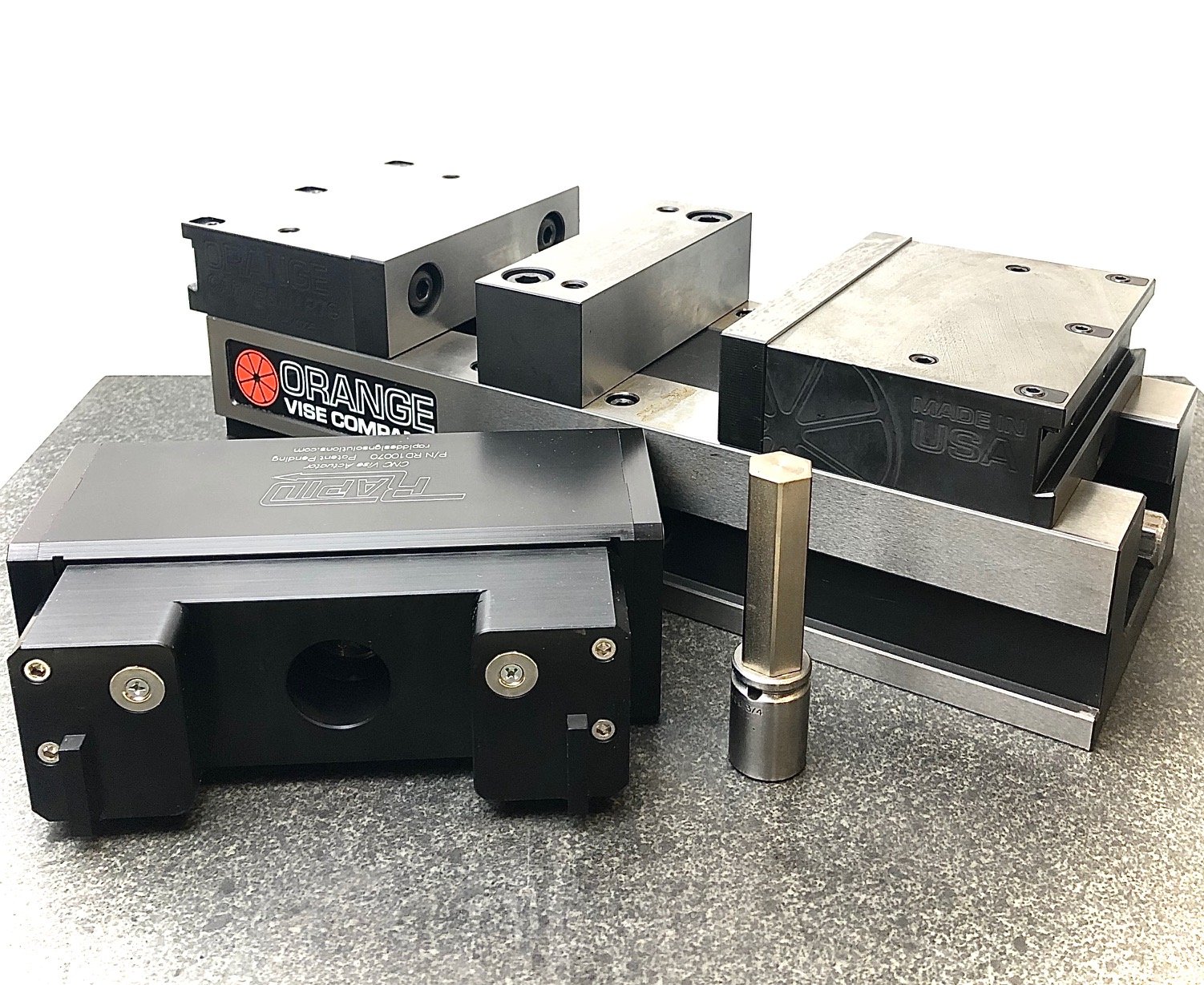

RoboWrench X5

The Longest Travel 5-Axis CNC Pneumatic Vise.

Do you or your team spend hours loading parts onto pallet pools or into vises? Now a robot can load a different part every time. You can now directly load high-mix parts with your robot.

Lead time is currently 8 weeks.

Made in the U.S.A!

HWR vise included. Other vises are available upon request.

The Longest Travel 5-Axis CNC Pneumatic Vise.

Do you or your team spend hours loading parts onto pallet pools or into vises? Now a robot can load a different part every time. You can now directly load high-mix parts with your robot.

Lead time is currently 8 weeks.

Made in the U.S.A!

HWR vise included. Other vises are available upon request.

The Longest Travel 5-Axis CNC Pneumatic Vise.

Do you or your team spend hours loading parts onto pallet pools or into vises? Now a robot can load a different part every time. You can now directly load high-mix parts with your robot.

Lead time is currently 8 weeks.

Made in the U.S.A!

HWR vise included. Other vises are available upon request.

50 ft-lbs working torque at only 100 psi

Patent Pending

Description:

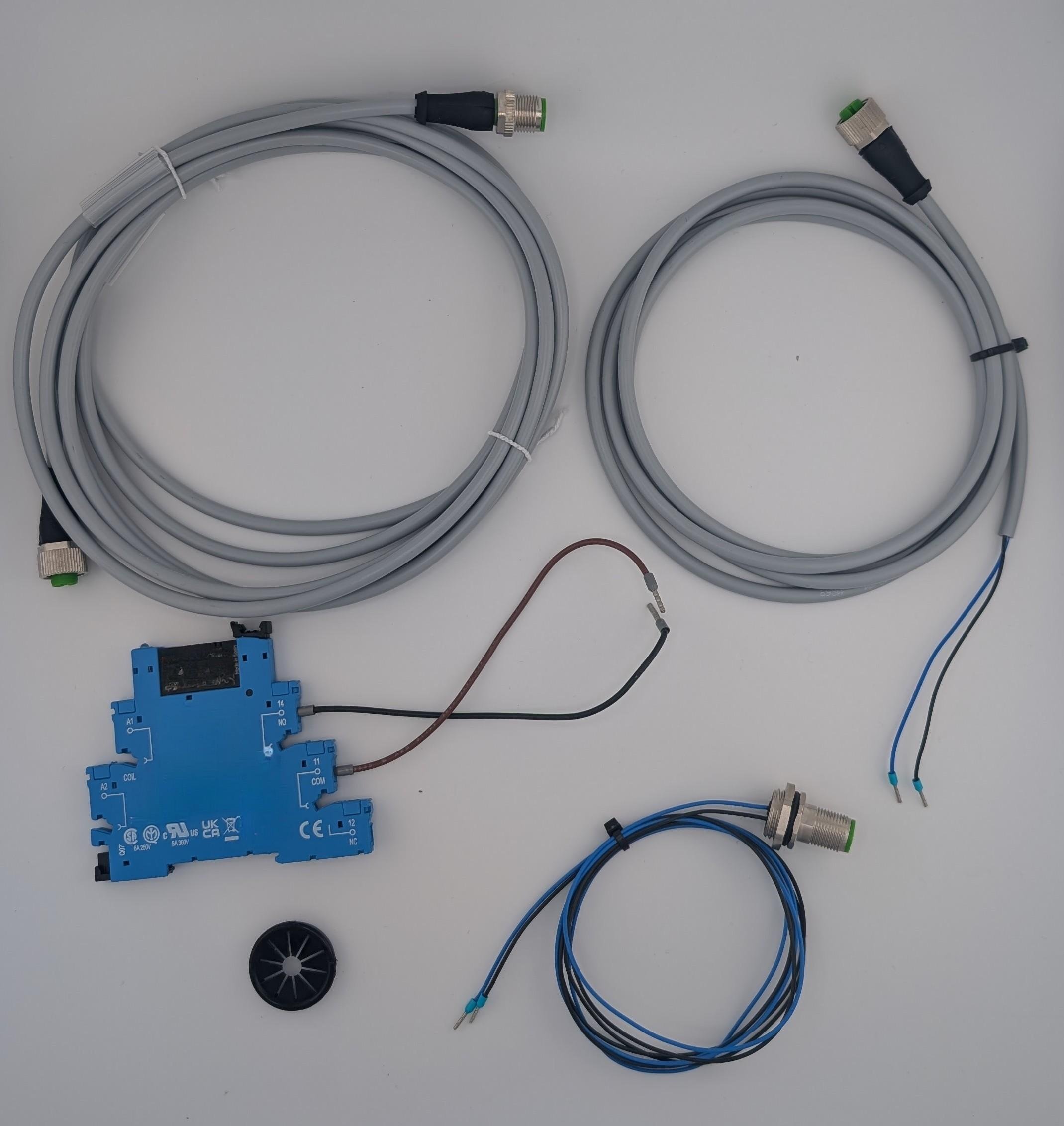

Looking for a pneumatic vise that offers unparalleled precision and versatility? Look no further than the RoboWrench X5. Designed to meet the demanding needs of modern machining, our pneumatic cnc vise stands out with its long travel distance, infinite rotation capabilities, and programmable jaw locations. You won’t need any other air vise than this!

Are you looking for answers to basic questions about pneumatic vises? See below or checkout a more complete list in our machine tending bible HERE

Common Questions

What is a pneumatic vice?

Also known as a CNC Pneumatic vise, an air vise, a Pneumatic CNC vise & sometimes an automated vise, A pneumatic vice is a clamping tool powered by compressed air, used to securely hold workpieces during various operations like machining. It offers quick, adjustable clamping force, making it ideal for tasks requiring precision and efficiency. Operated by a pneumatic cylinder, the force can be easily controlled, ensuring delicate workpieces aren't damaged. Commonly used in industrial settings, pneumatic vices enhance productivity, especially in repetitive tasks, and are safe for use in harsh environments.

What is a pneumatic vice used for?

A pneumatic vise is used in replacement of a manual vise but rather than having to tighten the vise by hand, the vise uses compressed air to open and close the vise. They are particularly useful when you need the vise to open and close quickly or when the vise needs to open automatically like when you need to load the vise with a robot. They also allow for easy adjustment of the clamping pressure of the vise, reduce setup time, and increase productivity.

What are the advantages of pneumatic vice?

Pneumatic vises have an advantage over manual vises through consistency, quick operation, easy adjustment, fast setup, and reduced risk of injury from manual operation. They remove the need for hand tools to operate them and can be used in conjunction with automation.

What is a machinist vise used for?

A machinist vise is used to hold a workpiece securely for machining operations, typically in a machine tool called a milling machine (or mill for short). These operations include but are not limited to milling, drilling, reaming, tapping, burnishing, etc. They are made to be very strong and to provide ample clearance to the workpiece.